impact hardness test|how hardness testing works : factories An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a . 6 dias atrás · A 888Bets tem uma aplicação para o sistema operativo Android disponível no site oficial da casa para download. Com a aplicação, o apostador tem tudo que a casa de apostas disponibiliza, e mais. A 888 .

{plog:ftitle_list}

25 de set. de 2022 · Notice. Overview: Milf’s Plaza is a non-linear story about a young adventurer from a big city. The main character, full of ambition and thirsty for thrills, is ready.

Impact testing is a convenient method for investigating high strain rate behavior, but there is a need for accurate and precise data collection. Here, we combine the precision and accuracy of .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .

Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or shocks. . The ductility and strength (measured by a tensile test), related hardness properties and fracture toughness (or impact resistance) are the . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .There are many kinds of tests performed to conduct testing of hardness. Testing of hardness is done by observing a steel ball pressed against the other material’s surface under tremendous pressure. Testing of hardness is done through the Rockwell Hardness test and the Brinell Hardness Test. There are also different types of hardness tests.

mechanical hardness test

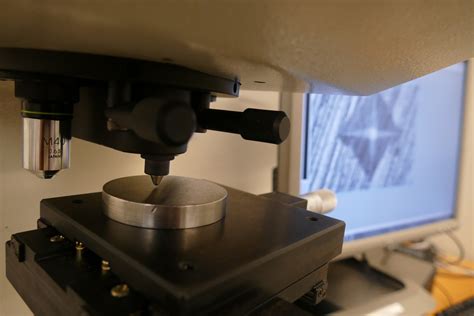

It also has an additional environmental chamber for high volume testing up to 300°C. Hardness testing. Hardness testing assesses the impact of the metal or alloy to permanent indentation, and the depth or size of the indent is measured to determine a hardness value. There are several different hardness tests and we use the Brinell, Vickers and .

HH-411 IMPACT TYPE PORTABLE HARDNESS TESTING UNIT. 2. HH-411 is a compact portable hardness tester that is user-friendly. A single touch of a button performs the non-destructive impact hardness . test so it's extremely easy to test workpieces on site. Equipped with data storage function. The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. The impact test is a method for evaluating the toughness, impact strength and notch sensitivity of engineering materials. . Impact resilience and scleroscope hardness are determined in nondestructive impact tests. The impact resistance of a part is, in many applications, a critical measure of its service life. More importantly, it affects .

impact hardness test kla

While the Charpy Impact Strength test and the Hardness test serve different purposes, they both provide valuable information about a material's mechanical properties. The Charpy Impact Strength test focuses on a material's ability to absorb energy and resist fracture under impact loading conditions, while the Hardness test measures a material's .

To the topic that concerns us, impact-abrasion wear, the authors showed under impeller-in-drum test conditions that the hardness did not correlate at all with the wear rate for the different commercial steels and irons used, as is shown in Fig. 7. In fact, the authors concluded that despite being a first good indicator of a material’s .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as . Hardness testing is qualitatively and quantitatively discussed with particular references to the various types of hardness tests. Impact testing is also explained, including the mathematical relationship to calculate the impact energy. Mechanical properties data are presented, wherever necessary. This chapter contains 12 diagrams, 14 worked .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

impact and hardness testing

Hardness testing is a mechanical test that measures a material's resistance to indentation, scratching, or abrasion. There are several types of hardness tests . Resistance to impact; Hardness Testing Considerations. The following sample characteristics should be considered prior to selecting the hardness testing method to use: Material;Impact Testing. E604-18 Standard Test Method for Dynamic Tear Testing of Metallic Materials . . Indentation Hardness Testing. E140-12B(2019)e1 Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness .

Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection .Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength 2. Functionality • Test to confirm ability to function as designed. • Wear Resistance • Toughness • Resistance to impact Hardness .

A single touch of a button performs the non-destructive impact hardness test so it's extremely easy to test workpieces on site. Equipped with data storage function A maximum 1800 data entries of hardness test results can be stored. This function is very useful for routine tests at work sites. Hardness testing on narrow surfaces is possible

Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes 8.8 - 12.9. .Since Proceq invented the Leeb hardness test principle in 1975, Equotip has become established as a globally recognized brand for portable hardness testing and a de facto industry standard. A wide range of different impact devices, as well as a comprehensive selection of test blocks and accessories cover most applications. The most common types of mechanical tests include Tensile test, Compression test, Hardness test, Impact test, Fatigue test, and Torsion test. Tensile testing. Tensile testing is a type of mechanical test used to measure the properties of a material when subjected to tensile forces. The test involves applying a controlled load to a sample of the . Impact testing serves to assess a material’s impact toughness, representing its resistance to impact forces. The ability to quantify the impact property is a great advantage in product liability and safety. This involves three main tests: the tensile impact test, the Charpy V-notch test, and the Izod impact test. Engineers use the Charpy .

After the first test, you can increase the weight of the pendulum’s hammer until it breaks the material, which would then signify that the impact strength value can be calculated. If you need to do an IZOD test in cold temperatures, the test material will be placed in a freezer until it reaches equilibrium, and then taken out and tested.Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated . In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation. Mechanical properties like Tensile Strengh, Ultimate Tensile Strengh, % of elongation, resistance to penetration, and hardness of Al-SiC-CSA composites were found using the tensile test, Charpy test, and hardness test at room temperature. (3) 88%Al, 6%SiC, and 6%CSA composites produced good Tensile properties due to 6% of SiC and 6% of CSA. (4)

how hardness testing works

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .impact test, Test of the ability of a material to withstand impact, used by engineers to predict its behaviour under actual conditions.Many materials fail suddenly under impact, at flaws, cracks, or notches.The most common impact tests use a swinging pendulum to strike a notched bar; heights before and after impact are used to compute the energy required to fracture the bar .

Detecht.co.id – Impact Test, Beberapa perangkat pada otomotif dan transmisi serta bagian-bagian pada kereta api, akan mengalami suatu beban kejut atau beban secara mendadak dalam pengoperasianya.Oleh karena itu ketahanan suatu material terhadap beban mendadak, serta faktor-faktor yang mempengaruhi sifat material tersebut perlu diketahui dan .

hardness testing techniques

hardness testing standards explained

Guaíra Mil Grau, Guaíra, SP. 13,209 likes · 273 talking about this. Não levem nada a sério! Sem mimimis, é nois Cidade de gente feliz

impact hardness test|how hardness testing works